OUR WASTE TREATMENT MACHINE ECODAS T2000

SUMMARY

Our patented process is designed to shred and sterilize infectious waste to reduce its volume, and render its components unrecognizable all in one fully enclosed and automated, stainless steel, system. It combines shredding, direct steam and high pressure to treat infectious materials.

The contaminated waste is loaded into the upper chamber where a heavy-duty, high-torque, low speed shredder reduces the waste into small pieces.

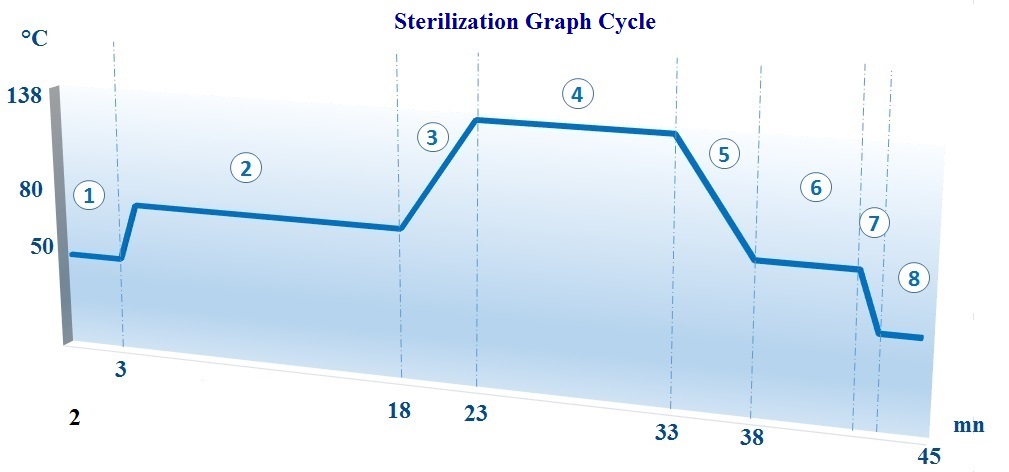

Using gravity, the processed material drop into the lower treatment chamber, where every particle is steam heated to 138°C (280 F) and pressurized to 3,5 bar (51 psi) for 10 minutes. The operating and treatment conditions are continuously monitored and validated to achieve complete sterilization (Microbial inactivation = 108).

After the cooling process, the final product is volume-reduced (by up to 80 %), rendered unrecognizable and safe to recycle or to dispose as ordinary municipal waste.

The 45 minutes duration of an average cycle process is fully automated and totally monitored. A computerized control system scans the process and automatically prints a batch report at the end of each cycle with the essential sterilizing parameters for accurate record keeping.

DATA SHEETS

GENERAL CHARACTERISTICS

| Dimensions ( L x l x H ) Dimensions ( L x W x H ) |

490 x 460 x 640 CM 16,1 x 15,1 x 21 F.T |

| Shipping Weight | 5200 KG |

| Max weight when filled with water For a special hydraulic test | 10500 KG |

| Stress | 3,5 KG/CM2 |

| Steam Pressure | 8 BARS |

| Max Steam Flow | 500 KG/HOUR |

| Compressed Air | 6 BARS |

| Electricity 380V / Three phase | 35 KW |

OPERATING CHARACTERISTICS

| Treatment temperature | 130 – 177 °C |

| Average Cycle Time | 45 MIN |

| Max Loading Volume Capacity | 2572 LITERS |

| Average Process Volume Capacity | 2500 LITERS |

| Average Waste Density | 100 – 150 KG/M3 |

| Average Process Weight Capacity | 250 – 375 KG/CYCLE 551 – 827 LB/CYCLE |

| Microbial Inactivation | 108 |

| Waste Volume Reduction | 80% |

| Max Waste Weight Reduction (depending on the nature of the waste) | 40% |

CONSUMPTION / CYCLE

| STEAM | 40 KG |

| ELECTRICITY | 9 KWH |

| WATER | 50 LITERS |

VIDEO

CASE STUDY

| Site dimensions | 150 M² |

| Average Cycle Time Load to Load | 45 MIN |

| Volume Capacity | 2500 LITERS / 660 GAL |

| Average Process Weight Capacity | 250-375 KG/CYCLE 551-827 LB/CYCLE |

| NUMBER OF SHIFTS | AVERAGE ANNUAL MACHINE CAPACITY |

| 1Shift – 40 hrs/wk | 866 T 1,908,664 LB |

| 2Shifts – 80 hrs/wk | 1733 T 3,819,532 LB |

| 3Shifts – 120hrs/wk | 2 600 T 5,730,400 LB |

EXAMPLE OF ACHIEVEMENTS

REFERENCES

ALGERIA – ENGLAND – ANGOLA – ARGENTINA – BRAZIL – CHINA – DENMARK – EGYPT – ECUADOR –FRANCE – FRENCH GUYANA – GHANA – GREECE –HONDURAS – HONG KONG – ITALY – JAMAICA – JAPAN – LIBYA – MOROCCO – MARTINIQUE – MEXICO – NEW CALEDONIA – OMAN – REP. CHECK – SINGAPORE – SLOVAKIA – SPAIN – THAILAND – TUNISIA – TURKMENISTAN – TURKEY – URUGUAY – USA

CERTIFICATIONS / APPROVALS

ECODAS The process has been tested by the Institut Pasteur de Lille, and approved by the Superior Council of Public Hygiene of France ( CSHPF ), under the Ministry of Health and the Ministry of the Environment (click to view document):

T2000 Homologation : March 1st 2013

The quality management of ECODAS systems is executed following ISO 9001:2015 and ISO 14001:2015 standards (click to view document).

The ECODAS T2000 complies with standard NF X30-503-1 (click to view document).

ECODAS Systems are designed and manufactured in accordance with the following norms (click to view document):